Recycling containers that stand out from the crowd

Success storiesJO-BA is one of Europe’s leading manufacturers of customised recycling containers

Kai-Uwe Jobst is full of ideas for recycling and sustainability. In 2009, he took over his father’s Bremen-based business, JO-BA, which specialises in developing and manufacturing recycling systems. The company is now a well-established brand in Europe – anyone recycling old clothes, shoes or electronic waste is likely to throw them into recycling containers made in Bremen.

Colourful recycling containers with memorable slogans

You cannot fail to notice the bright yellow metal bin, emblazoned with a catchy slogan, and that is exactly the thinking behind it. It has been designed to be conspicuous, so that dog owners know immediately where to put the bags containing their four-legged friends’ waste. The man behind the design is Kai-Uwe Jobst, managing director at JO-BA GmbH, who came up with the idea during one of his many walks along Bremen’s Werdersee Lake with his dog, Luke. “It really annoys me when I see carelessly discarded plastic bags in the forest or on the grass,” he says.

Jobst, a qualified lawyer, is full of ideas about recycling, sustainability and the sensible use of resources. When he joined his father’s company in 2004, the business had already switched its focus towards recycling. But it was only once he joined that the business really took off. And that has a lot to do with his ideas.

From slurry tankers to recycling containers – and from Bassum to Bremen

The company was originally founded by Horst-Dieter Jobst in 1972 as Stall- und Regentechnik GmbH. The new company name is composed of the first two letters of the family name and of Bassum, the town near Bremen where the company used to be based. During the early years, the company specialised in the manufacture of slurry tankers and slurry silos. However, when the company made its first clothing collection container in 1984, it marked the turning point that would lead to the renaming of the company to JO-BA Maschinen- und Anlagenbau GmbH. In 1998, JO-BA GmbH moved its headquarters to Bremen.

When Kai-Uwe Jobst became managing director in 2009, he moved the entire container production to Germany and made individuality the company’s USP – changes that define the company as it is today. “Anyone can do sheet metal,” says the 45-year-old. “The art is in making your containers stand out from the rest.”

Customised containers – from their shape to their livery

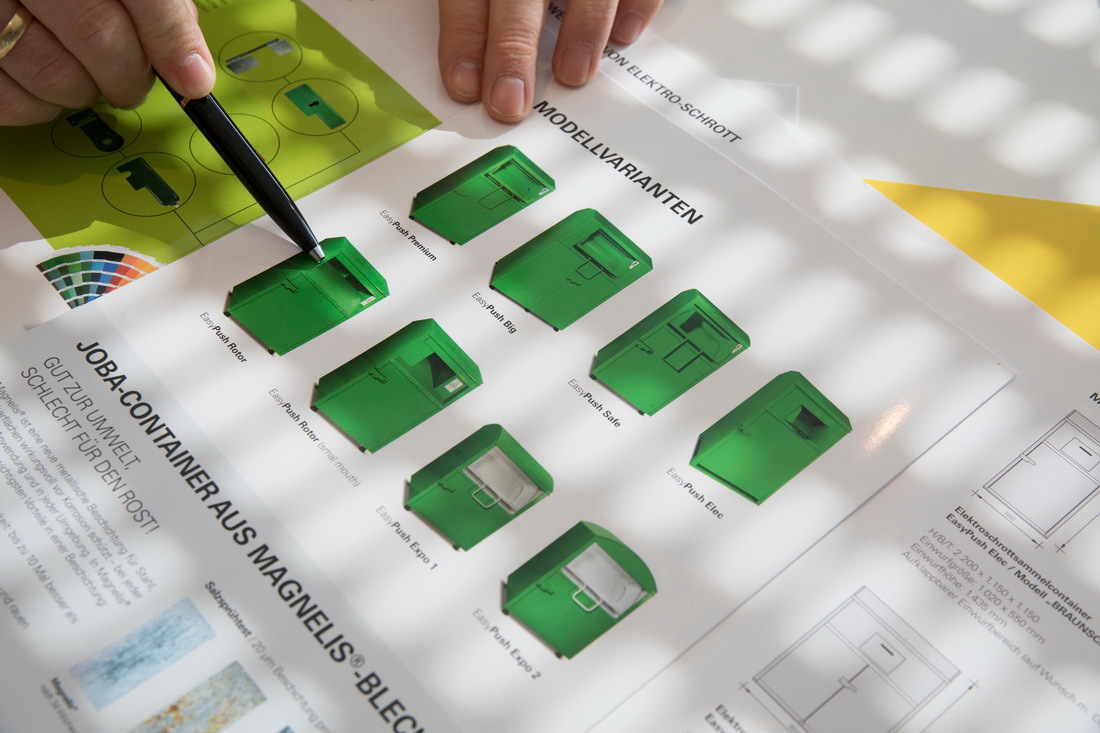

And this art begins with the shape. Not only can customers choose from a variety of sizes, there is also a range of inlet, chute and handle shapes, and even the roof is available in several versions. Thanks to a modular system, they can all be combined to meet individual requirements. “Our customers can choose from round roofs, angled roofs or a tailor-made solution,” Jobst says. For example, JO-BA has developed mushroom-shaped collection containers for children’s shoes that are used in shoe shops.

Eco-friendly powder coating

A wide range of colours is available, including red, blue, yellow, green, white and pink. JO-BA has its own production facility on the Bremen Hansalinie Industrial Estate where the metal surfaces are given their powder coating. “Our powder coating technology is environmentally friendly and ISO certified,” says Jobst. Each part goes through the automated coating machine and is fully covered before it is used. “This means that our containers are far more durable, and they can also be multi-coloured. Thanks to the seamless coating, the metal sheets are far more resistant to corrosion,” he adds. The containers are designed to be rust-free for up to 15 years.

Inhouse graphic designers give the containers an individual look

The unmistakeable look of the containers is enhanced by the adhesive films that are designed inhouse. They are what makes a container what it is – a collection point for either old clothes, shoes, glasses, medication, general waste, electronic waste or dog waste. In short, anything that can be collected and recycled.

Germany’s only manufacturer of clothing collection containers

An entirely custom-made container costs around €500, according to Jobst. The Bremen-based company currently manufactures between 8,000 and 10,000 units a year for customers in Germany, France, Greece, Italy and Switzerland. “We are the only manufacturer of clothing collection containers in Germany, and one of the market leaders in Europe,” Jobst says proudly.

Supporting reforestation projects through carbon-neutral collection containers

But Jobst is interested in more than just selling containers. He is also concerned about sustainability and social compatibility, especially when it comes to recycling old clothes, which is the core business of the majority of his customers. “The clothes recycling sector has a bad reputation, as there are many black sheep and illegal collections,” Jobst says. The fact that the trade in cheap textiles from Europe is robbing African manufacturers of their livelihood, worries him and has spurred him into action.

Carbon-neutral containers for reforestation projects in Ethiopia

He has joined forces with the World Forest Foundation and the consultancy firm CO2OL to develop a carbon-neutral container: “We have calculated the carbon footprint of a container, i.e. how much CO2 is emitted in making it. To compensate for this, our customers can purchase CO2 certificates to the value of €12. The proceeds are used to finance reforestation projects in Ethiopia,” Jobst explains.

15 hectares of forest have already been planted

For Jobst, it is about more than just climate change: “The reforestation project is also creating new jobs and a new value chain. Our aim isn’t to pay our way out of our obligations – we want to show people that there are alternatives.” According to Jobst, his customer’s contributions have paid for more than 15 hectares of forest so far. “The project is particularly popular in Switzerland. Our Swiss customers account for 15,000 trees.”

Community-based projects for clubs and schools

The 45-year-old is also focused on projects in Germany, including an initiative whereby the proceeds from donated clothes and shoes help sports clubs to nurture young talent. In Bremen, JO-BA is working on a joint project with Impuls Deutschland, a foundation that supports disadvantaged children and their families, and the textile recycling company FWS. The project will see clothing collection containers placed at around 50 sites across the city. “The proceeds will fund community projects in problem schools,” Jobst says. He is already planning a similar project in Berlin, where the money made will be used to support the homeless.

Press contact

JO-BA GmbH, tel: +49 (0)421 410 044, email: info@jo-ba.de

Success Stories

Medium-Sized Companies in Bremen Showcasing the Full Range of the Local Economy

Medium-sized companies form the backbone of Bremen’s economy. They create jobs and produce goods that are in demand worldwide. Here is a selection of ten businesses that illustrate the diversity of Bremen’s economic landscape.

Learn moreMeasure, Test, Inspect – 11 Examples of Precision Engineering from Bremen

Not many people could name a manufacturer of metrology and testing equipment, but without their products we would not have space probes, aircraft or medical equipment. And Bremen is home to a whole host of these specialist companies.

Learn more8 Bremen Companies involved in Mass Spectrometry

If you want to get down to the smallest building blocks of our world, you need mass spectrometers. And there are few places in the world where there is such a high concentration of specialists and manufacturing companies and suppliers in this sector as in Bremen.

Learn more