Bremen is one of Germany’s leading industrial hubs

Success storiesIndustrial infrastructure with potential for the future

Bremen is Germany’s tenth-largest industrial hub in terms of gross domestic product (GDP). Whether it is about planes and satellites, foodstuffs, automotive, shipping, logistics or steel production, Bremen´s industrial sector has always been a major player.

The structure of Bremen’s gross domestic product (GDP) reveals how important industrial companies are for economic output and how heavily the state’s industry is geared towards exports. Bremen has extensive links with the global economy and has the highest export rate of all federal states (55,2 percent). The promising potential of this industrial infrastructure lies in the successful combination of international business and sales relationships, strong regional economic ties and outstanding locational factors.

The ports are the hub for the global flow of goods

More than ever, Bremen’s ports are an important hub for the global flow of goods. They include Germany’s second-largest seaport, Germany’s tenth-largest inland port, the state-of-the-art Cruise Terminal Bremerhaven, Europe’s second-largest car terminal, which handles more 1.7 million cars a year, and Northern Europe’s fourth-largest container hub, which currently has 14 berths for large container ships.

Around a fifth of all jobs in the state of Bremen are connected to the ports, which also account for a fifth of revenues and a quarter of value added. Around 10,000 jobs in the surrounding area of Lower Saxony also depend on the ports.

Back in 1966 in Bremen’s Überseehafen, the US vessel Fairland delivered the first container to a German quay, kicking off a revolution in maritime transport and the transshipment of goods. Since then, the size of the ships used in international container transport has grown steadily – the largest ships today carry more than 24,000 container equivalents (TEU). Bremen’s ports are traditional railway ports with a well-developed rail infrastructure that features 192 kilometres of track in total. More than a million containers are transported by rail every year via inland links.

Around 50 Bremen-based port companies and industrial businesses have joined forces in Initiative Stadtbremische Häfen e.V. (ISH) to promote and strengthen the port economy. The majority of these are headquartered in Bremen’s Holz- und Fabrikenhafen and in Europahafen in Überseestadt. “Small and medium-sized businesses are pooling their interests in ISH in accordance with the ‘Bremen model’, which envisages the compatible co-existence of industry, ports, trades, services and residential areas,” says ISH managing director Heiner Heseler, summarising the initiative’s goals. Together, these businesses have revenues of around €3 billion and represent approximately 6,000 jobs.

Car manufacturing is a star performer

Bremen has been an important centre of the automotive industry for generations. The first car plant in Bremen opened in 1906, and its first celebrity customer was none other than Kaiser Wilhelm II. Where Carl Borgward once built his legendary cars, Mercedes-Benz now assembles its vehicles. According to the 2023 annual statistical report, the yearly revenue generated by vehicle manufacturing (excluding ship and boat building) is around €20.1 billion.

With a workforce of around 12,500 people, the Mercedes-Benz plant in Bremen is the region’s largest private-sector employer and manufactures more than 400,000 vehicles a year. As the world’s second-largest Mercedes-Benz plant, it is the centre of excellence for the C-Class, and it also manages the production ramp-up of this model in the USA (Tuscaloosa), in China (Beijing) and in South Africa (East London). Modern electric vehicles also roll off the production line here.

Suppliers account for around three quarters of a car’s value added. Bremen-based suppliers include Hella Group, Lear Corporation, Brose Group and Kuka Group. A few kilometres away from the Mercedes-Benz plant is the busy Bremen Hansalinie Industrial Estate, home to many companies in the automotive sector.

Bremerhaven is not only home to Europe’s largest car transshipment centre but also to its largest car workshop, the technology centre of BLG Logistics Group. Up to 500,000 export and import vehicles are inspected, processed, retrofitted and upgraded – for example with sunroofs, sat-navs, media systems or leather seats – here every year.

Bremen’s ports are a logistics hub for the entire automotive industry. Parts and kits are shipped from here to assembly plants all over the world. In addition to the universities, outstanding scientific institutions in Bremen are researching future solutions for the automotive sector. The BIAS Bremer Institut für angewandte Strahltechnik, the BIBA Bremer Institut für Produktion und Logistik, the DFKI Deutsches Forschungszentrum für Künstliche Intelligenz, the FIBRE Faserinstitut Bremen, the IFAM Fraunhofer Institute for Manufacturing Technology and Applied Materials Research, the IWT Stiftung Institut für Werkstofftechnik, the BIME Bremer Institut für Strukturmechanik und Produktionsanlagen, among others, focus on the automotive sector here.

Aerospace takes off

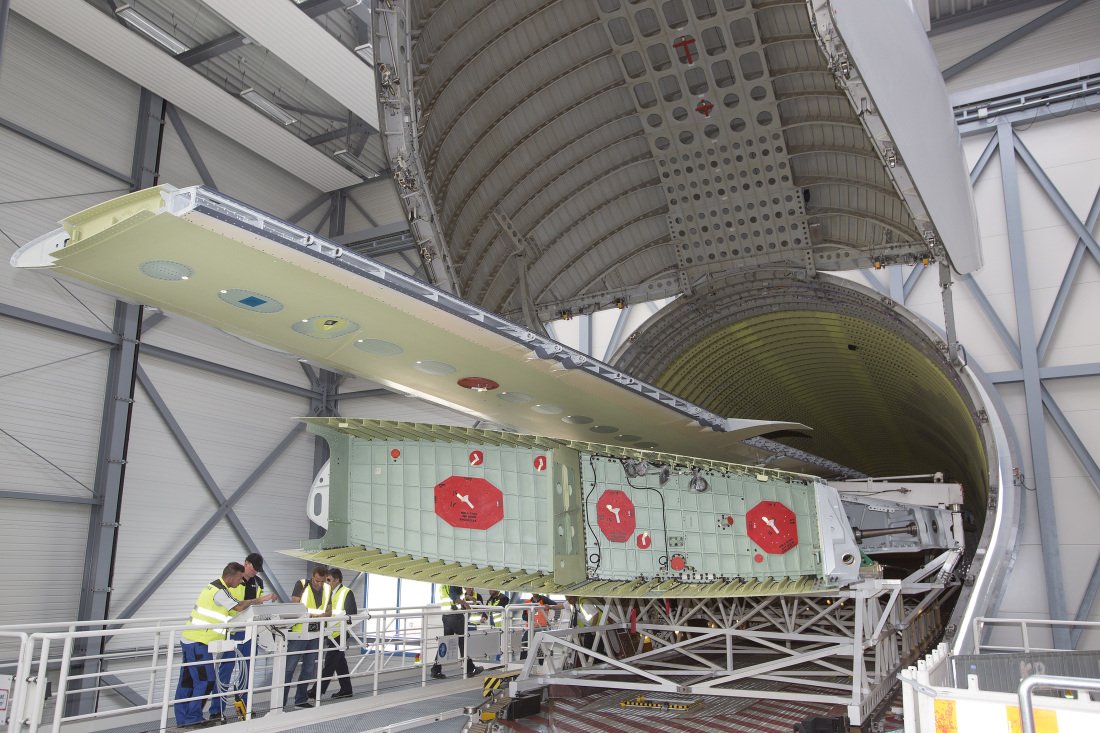

Every year, the who's who of the industry meet at Space Tech Expo Europe in Bremen. The event underlines Bremen’s international standing as an established hub for the aerospace industry. A higher proportion of people work in the aerospace sector in Bremen than anywhere else in Germany. Around 12,000 employees across 140 companies, including major enterprises such as Airbus Group, Ariane Group, OHB SE and their suppliers, as well as 20 research institutes generate revenue of more than €4 billion a year. Key products made here include wing equipment for Airbus aircraft, the upper stage of the Ariane rocket, modern earth observation satellites, the Galileo satellite navigation system and the propulsion technology for the future NASA ORION spacecraft..

The wings for the A330 and A350 long-haul aircraft are fitted out at the Airbus plant in Bremen. The development and manufacturing centre for high-lift devices for all Airbus programmes is located here, and Germany’s second-largest Airbus site is heavily involved in the development and manufacture of the A400M transport aircraft. The cargo loading systems for the entire Airbus fleet are also designed here, and materials and process development provides an additional focus. The AVIASPACE BREMEN e.V. industry association implements the aerospace strategy of the state of Bremen and maintains close links with other high-tech sectors, including the automotive, wind energy and ship building industries.

At the ECOMAT Technology Center, around 500 scientists are laying the foundations for the future of climate-neutral flight: they are researching propulsion systems, particularly in the field of hydrogen fuel. This is where expertise in the fields of space travel and aviation come together.

Bremen’s famous food brands

The food and drink industry is the second most important manufacturing sector in the state of Bremen. The sector, including wholesalers, employs more than 10,000 people and generates annual revenue of around €2.5 billion. Mondelez, the world’s seventh-largest food company, has its German headquarters in Bremen. Numerous service providers in the areas of logistics, warehousing and transport, as well as testing laboratories and specialised research facilities, have established themselves here. Many internationally known brands originate in Bremen, and according to NaGeB, the trade association of the food and drink industry in Bremen, this sector accounts for almost 25 per cent of imports and almost 10 per cent of exports in Bremen.

The association estimates that millions of hectoliters of beer are produced and the largest amount of coffee in Germany is handled and processed in Bremen. The industry's wide range of products in Bremen extends from beer, wine and coffee to rice, sauces, cream cheese and fish through to chocolate and pet food - many products from Bremen are well-known around the world.

The steel industry – from pig iron to sheet metal

ArcelorMittal Bremen GmbH is an integrated steelworks located to the north of Bremen on an approximately seven square kilometre site on the banks of the river Weser. It produces everything from pig iron to sheet metal. ArcelorMittal Bremen is part of Luxembourg-based ArcelorMittal, the world’s largest steel company. It is one of the region’s largest employers and reportedly has the capacity to produce over 3.5 million tonnes of steel a year. Key customers of the Bremen-based steel company include Europe’s leading vehicle manufacturers, the mechanical engineering sector and the construction, packaging and household appliance industries.

The steelworks employs around 3,000 people. According to a recent study by the Bremen Chamber of Labour, a further 4,700 people work in jobs that are indirectly dependent on the steelworks. According to these calculations, as many as 19,000 jobs throughout Germany depend on it. ArcelorMittal Bremen generates more than 30 percent of its revenue in Bremen and almost a quarter of its suppliers are based locally, underlining the huge importance of the steel producer to the region’s economy.

Hydrogen and renewable energies

Bremen is one stop on the road to a climate-neutral future. The state is one of the pioneers in wind energy. Wind turbines and wind farms have been designed and produced in Bremen since 1990. Numerous companies from the sector are still based in the state today. These include project developers such as wpd and Energiekontor, which install and operate wind turbines worldwide. As a loading port for components, Bremerhaven plays a role in the expansion of offshore wind energy in the North Sea.

The industrial activities are accompanied by an ultra-modern research landscape, including one of the largest test stands for rotor blades. At the Fraunhofer IWES, bolides up to 120 meters long can be put through their paces.

Alongside wind energy, the hydrogen economy has picked up speed in recent years. Northern Germany offers an ideal field of application for the hydrogen economy due to the high energy production of renewable energies. Several large-scale industrial projects are currently being planned. These include, for example, the construction of a 10-megawatt electrolyzer to produce hydrogen for the Bremen steelworks. Bremen wants to position itself as a central driver towards the use of hydrogen.

In addition to climate-neutral steel production, the mobility sector is also part of the hydrogen transition. Companies such as Airbus and numerous institutes are researching hydrogen-powered aircraft, while the young company ENGINIUS produces hydrogen trucks in Bremen. A hydrogen infrastructure is being created in numerous places in Bremen, including the port.

Cross-sector industries help shape the future

Bremen is considered one of the hotspots for industrial 3D printing. For example, the metal 3D printing center of the Belgian Materialise Group is located here. And research institutes such as IFAM and IWT are also helping to shape the industry here. 3D printing is a technology of the future that has long since become part of everyday life here and is used in numerous industrial sectors. In Bremen, cross-sectional technologies such as 3D printing are the glue that connects sectors and brings research and industry together. Another important technology is lightweight construction – not only in aircraft construction or aerospace, but also in the automotive sector. Finally, the IT industry – especially the artificial intelligence sector – is also an important cross-sectoral industry in Bremen. The Hanseatic city is a European center, especially in the field of robotic AI. Around cutting-edge research from institutes such as the DFKI or the Institute for Artificial Intelligence IAI, young companies have been founded that are setting off into the future with new ideas.

Success Stories

10 Leading Coffee Companies from Bremen

From trading to roasting to logistics – no one does coffee quite like Bremen. But who are the players driving the business in Germany’s coffee capital? Meet ten of them.

Learn moreThe history of space travel in Bremen

Small circle, big impact: With the founding of the “Development Ring North” (ERNO) in July 1961, Bremen began its development into one of the world’s leading spaceflight locations. Even the return of humans to the Moon would hardly be possible without technology from the Hanseatic city.

Learn moreMedium-Sized Companies in Bremen Showcasing the Full Range of the Local Economy

Medium-sized companies form the backbone of Bremen’s economy. They create jobs and produce goods that are in demand worldwide. Here is a selection of ten businesses that illustrate the diversity of Bremen’s economic landscape.

Learn more