3D printing at Airbus – cutting-edge technology made in Bremen

3D printingAirbus is leveraging the potential of additive manufacturing in the aerospace industry

Airbus is a global trailblazer in the field of 3D printing, and the aerospace company has established a technology centre for this new production method in Bremen. This is one of many reasons why the Hanseatic city has become a hub for 3D printing in Europe.

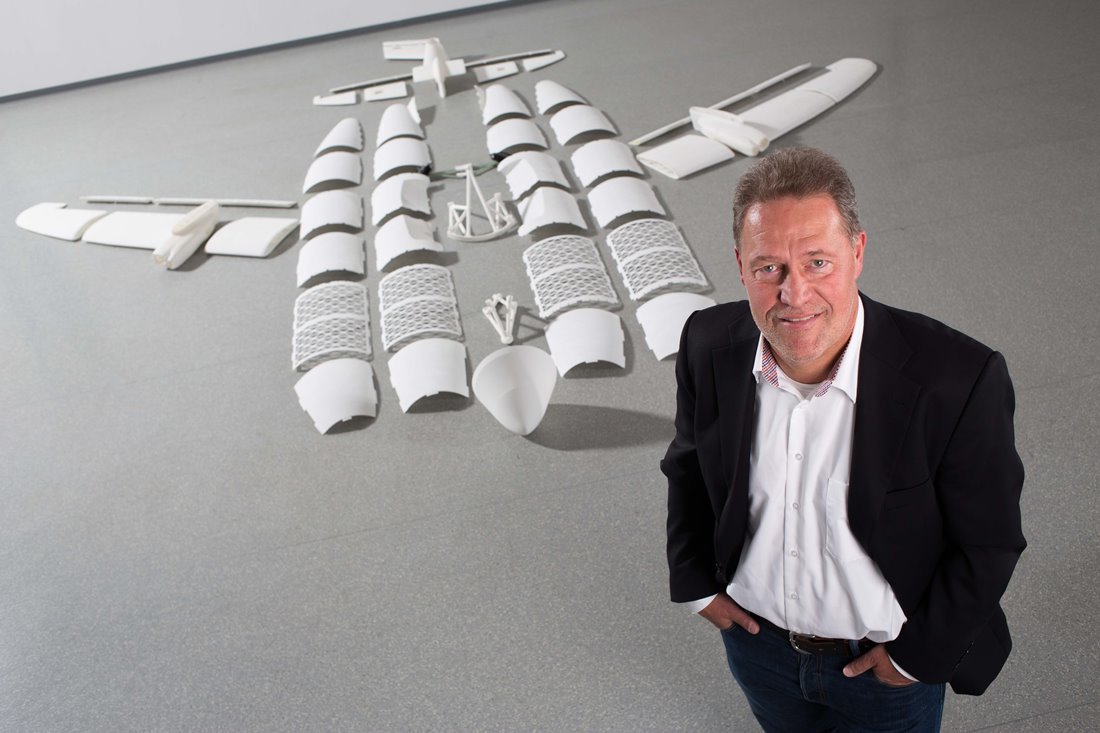

Peter Sander is a 3D printing expert in the Emerging Technologies & Concepts department at Airbus and a pioneer in the industrial use of this additive manufacturing method. Here he tells us how the global company successfully deployed the technology and how small and medium-sized companies can take advantage of it too.

Mr Sander, how important is 3D printing to Airbus?

Sander: The material and process developers at Airbus in Bremen have been working in this field for more than 15 years, initially with a particular focus on plastics. In its infancy, rapid prototyping* was not suitable for wide-scale industrial use and therefore had little impact in the company. This has changed considerably over the last five to ten years, and 3D printing is now used throughout the company. Everyone has recognised that 3D printing has great potential.

*Fast manufacture of sample parts/prototypes using 3D printing.

How did this come about?

Sander: We founded an ‘innovation cell’ at Airbus in 2010. This was a self-organised interdisciplinary team that was able to work outside of the usual top-down processes. The intention was to develop innovative technologies that bring quick results and to demonstrate how they work in practice. The initial focus was on 3D printing and automated design. We looked for experts and use cases, and created inhouse campaigns to promote the new manufacturing method across the group. The campaigns were particularly helpful.

How are these campaigns contributing to the process of innovation at Airbus?

Sander: The campaigns are Europe-wide calls for suggestions on how to use new technologies. The most effective campaign for 3D printing ran in 2014, when we received around 200 suggestions in just six weeks. After a three-month analysis and manufacturing phase, the 13 finalists presented the possibilities of 3D printing to senior management at Airbus. The outcome was a request to establish a Europe-wide 3D printing platform, with the aim of facilitating the introduction of 3D printing in industrial processes. The platform has been in operation throughout Airbus Commercial – i.e. aeroplanes – since the end of 2014.

What is the platform’s purpose?

Sander: It organises the development of materials and processes, creates new design tools and reviews use cases. The Europe-wide platform has more than 40 employees in Germany, the UK, France and Spain, and is driving forward the use of 3D printing within the company. Last year, we invested almost €10 million and have budgeted for a similar amount this year.

What successes have you had so far?

Sander: 2014 saw the delivery of the first printed plastic spare part to a customer and the first test flights using printed parts, such as a titanium bracket. It was important to show that 3D printing is a viable option for aviation. Last year, for example, we worked with Liebherr on a global first: We conducted a test flight with a printed hydraulic flight control component made of titanium, with a casing that is 55 per cent lighter than the previous model. It works perfectly and is still in use in our A380 test plane.

The objective is to start full production of such components in 2020. We have slowly worked our way towards this, initially by manufacturing the brackets in volume and then by turning our attention to larger projects. In Bremen, for example, we are now working on the preliminary development of highly integrated hydraulic components.

Several of our projects have been praised at the highest level. Our titanium bracket made it to the finals of the 2015 Deutscher Zukunftspreis, the German President’s Award for Innovation in Science and Technology. Our bionic partition design won the Federal Environment Ministry’s Ecodesign Award. And our four metre long THOR even made it into the Guinness Book of Records in 2018 as the world’s first 3D-printed aircraft that can fly.

What are the advantages of using 3D printing in aviation rather than traditional methods?

Sander: The range of potential applications is huge. Instead of storing hundreds of spare parts in a warehouse somewhere and having to transport them to their destination, in future we will be able to manufacture them on demand and where they are needed using additive manufacturing (AM). The result is a massive reduction in the resources needed. Another major area for AM is bionic, i.e. topology-optimised, manufacturing. This method uses fewer resources to create a product that is considerably lighter, which in turn reduces the amount of resources used in day-to-day operation. In future, we will also see highly integrated, multifunctional components created using AM, which will represent a step change in product design. This development potential will ensure that 3D printing goes mainstream.

Can any product be 3D printed?

Sander: It is all about identifying use cases. Not all materials are suitable for 3D printing, so there is still a considerable need for development. When I talk of metal, for example, I will always mean a material that is weldable. Airbus uses a range of aluminium alloys, each with a specific property and use, but not every alloy can be welded.

Sander: I can give you an example. We were working on printed aluminium cooling plates for satellites. This is an area where extreme temperatures are common, so thermal balance is important. There is a special material for this, but it was considered unsuitable for 3D printing. With funding from the German Aerospace Center (DLR), we worked with the Fraunhofer Institute for Additive Production Technologies, or IAPT, (formerly the LZN) to assess five materials for their suitability for 3D printing. This involved grinding them to a powder and checking whether they are weldable. Two of these were found to be suitable, one of which had been deemed unsuitable for aviation applications because it was thought to lack weldability.

Should small and medium-sized enterprises (SMEs) get involved in additive manufacturing now or wait a bit longer?

Sander: I would definitely say get involved now. But it is important that SMEs check which parts would benefit from 3D printing. Perhaps a part that is difficult to deliver because a cast part is missing, for example. It is possible to print complex products, but it makes sense to start off with a simple small bracket, just to determine that it is viable. The ‘lessons learned principle’ is the best approach here.

What is your advice for companies, including SMEs, that want to get involved in 3D printing?

Sander: I would recommend doing some networking. Some SMEs lack expertise and are unaware of the full potential of new manufacturing technologies. This is where we in the network can help. Especially when you consider that speed of development will be a key factor for survival in the marketplace. How can I quickly turn my new development into a viable product? The costs of innovation are often too high for a single company to bear, so having a network of partners to call upon can be helpful.

In this respect, we in the BRE3D initiative have plenty to offer: Support is available from various research institutes that we have been working with for many years in the fields of materials science and process engineering (IFAM, IWT, ISEMP, Faserinstitut) and in bionics (AWI), as well as the Chair of Bionics at Bremen University of Applied Sciences, held by Professor Antonia B. Kesel.

What about the cost?

Sander: In my experience, getting into 3D printing is not expensive. If you have an idea, you can take it to a specialist such as Bremer Unternehmen Materialise GmbH and develop an initial prototype with their expert help. The initial investment is not high at all, and the rollout to full production only happens later on. Companies do not even need their own 3D printer to get started, which means the transition can be gradual.

Thank you for talking to us.

Success Stories

Take-off for Bremen: what makes the city a hub for aerospace expertise

The sky is not the limit. Science, production, development and business all agree on this. Aircraft wings, Ariane rockets, Galileo satellites - Bremen is one of the top locations in the international aerospace industry. Five reasons for Bremen's success story.

Learn more“After all, we're here because someone else made room for us, and it's our duty to do the same for others”

Theoretical physicist, industrial mathematician, manager – as a member of the start-up company TOPAS, Dr. Shruti Patel creates change in Bremen. However, being a role model has not always been easy for her.

Learn more12 Examples of AI in Medicine and the Health Sector

Detecting cancer earlier or avoiding accidents at work - AI will make our lives easier and easier in the healthcare sector. In Bremen, a strong AI landscape is developing in the healthcare sector, as these 12 examples show.

Learn more