ECOMAT – a technological milestone

ECOMAT / lightweight constructionKey technologies brought together at Airport-Stadt Bremen.

Policies that boost innovation aim to support the ongoing structural change in industrial companies, SMEs and related service providers. Promoting promising technologies is a particularly important part of this. Some technologies feed into each other, such as additive manufacturing, 3D printing, lightweight construction and bionics. The automotive, maritime, and space and aeronautics industries, which all have strong clusters in Bremen, offer great potential for additive manufacturing and 3D printing. But there are also interesting potential uses in healthcare technology and the food sector.

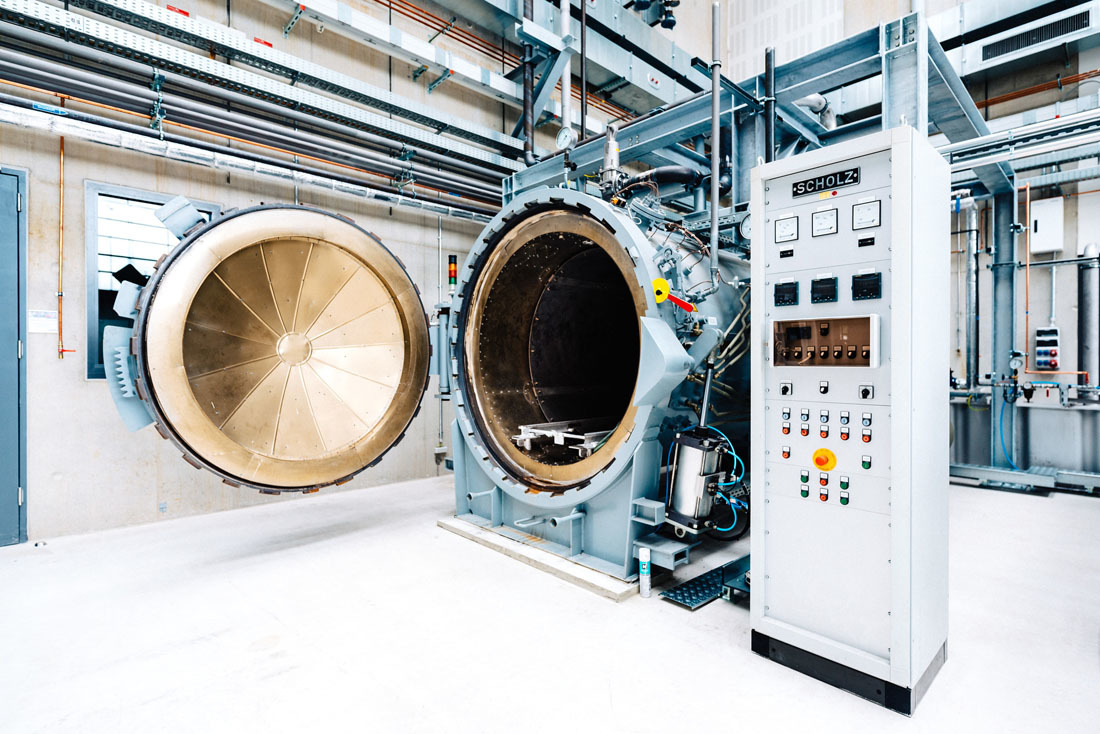

Bremen has pooled local industry and research expertise in the field of lightweight construction and associated key technologies, in particular additive manufacturing, in the ECOMAT research and technology centre at Airport-Stadt Bremen. This gives small and medium-sized enterprises, in particular, access to key technologies and enables them to strengthen their ability to innovate and be competitive.

Quality ingredients

Getting the ECOMAT – the Center for Eco-efficient Materials & Technologies – up and running has certainly not been straightforward. Countless planning and coordination meetings, a complex construction phase, and then a flying start in May 2019. But that is all water under the bridge now. What matters is the commitment and motivation that was evident among the high-calibre users of this research and technology centre as soon as they moved in. It is a bit like cooking: quality ingredients increase the chances of a quality outcome.

A mere three years passed between the ground-breaking ceremony in April 2016 and the opening ceremony in April 2019 – very quick for a €73 million investment offering 21,800 square metres of net floor space. “Industry professionals consider ECOMAT to be an exceptional building,” says Dr Bernd Haustein, Head of Real Estate and Construction, looking back. Together with architect Heiko Latos and a handful of employees, Haustein was in charge of the project for H.A.G.E. Grundstücksverwaltungsgesellschaft mbH, a subsidiary of Bremeninvest, when it came to the Europe-wide invitations to tender for the project. There were no previous examples to look to for guidance. Functionality, structures and costs had to be defined in advance, sometimes in consultation with future tenants, without being able to accurately assess the desired outcome.

The infrastructure

Center for Eco-efficient Materials & Technologies

ECOMAT Airport-Stadt Bremen

Cornelius-Edzard-Straße 15

28199 Bremen

- Net floor space: approx. 21,800m² (laboratories, technology centre and offices) on four floors, consisting of approx. 11,500m² usable rental space and approx. 10,300m² of building service areas, circulation areas and communal space;

- Anchor tenants: Airbus Operations GmbH, TESTIA GmbH, Ariane Group, Bremen Fibre Institute (FIBRE) and German Aerospace Center (DLR);;

- Other science and research tenants: Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM), Leibniz Institute for Materials Engineering (IWT);;

- Around 500 experts from a wide range of research disciplines and specialisms.

Airbus: new collaborations in new surroundings

Airbus, its subsidiary TESTIA GmbH and Ariane Group (space exploration) are among ECOMAT’s biggest anchor tenants. 311 Airbus and around 30 to 40 TESTIA employees are working on the aircraft manufacturer’s key projects at the research and development centre. “We have around 250 people working at ECOMAT on two main pillars – testing and the development of materials and processes. A further 60 or so employees are developing new high-lift systems, that is to say new technologies for next-generation wings,” says Dr Hubertus Lohner, outlining the Airbus strategy at ECOMAT.

Lohner provided support during the planning stages and the move, and now coordinates the Airbus activities on site. ECOMAT will drive further research into topics for the future on which work has already been carried out: alternative propulsion systems, sustainable flight operations, and the simulation and modelling of the aircraft development cycle. The proximity to the space division of Airbus Defence & Space presents an opportunity to concentrate and consolidate activities on site, particularly in the area of tank and distribution systems and associated materials and certification processes.

Efficiencies are also the focus of the collaboration with partners in Bremen’s new technology and research centre. According to Lohner, proximity to partner organisations at ECOMAT is very important. A whole host of cooperation agreements have already been signed, including with the Fraunhofer Institute, with the aim of sharing equipment, personnel and laboratories. Similar agreements with the Leibniz Institute, the Fibre Institute and the German Aerospace Center are in the pipeline.

“We want to work closely with our partners. We can see in our day-to-day work that there are efficiencies to be gained, and that direct contact on site makes work much easier for all of us.”

Dr Hubertus Lohner (Airbus), Director and Coordinator of ECOMAT

Airbus employs around 19,000 people in its commercial aircraft division in Germany. The site in Bremen employs around 2,300 people in commercial aircraft production, making it the second-largest site in northern Germany alongside Hamburg, Stade and Buxtehude.

Virtual Product House – a platform for numerous specialist fields

It is only logical that the German Aerospace Center, the national research centre of the space and aeronautics industries, is now located at ECOMAT, virtually next door to Airbus. There, the German Aerospace Center focuses on projects related to the Virtual Product House (VPH). The VPH, an integration and test centre for virtual simulations and the certification of aircraft components and technologies, is the result of close cooperation between partners from industry, the research community and public bodies.

“The German Aerospace Center’s strategy for virtual certification aims to reduce the time and cost of certification tests by providing supplementary virtual flight and ground tests. Furthermore, seamless digitalisation should enable more efficient development processes for innovative and environmentally friendly aircraft,” says Dr Kristof Risse, Head of the VPH, Programme Directorate Aviation, outlining the approach of this ambitious venture.

According to Risse, the long-term aim is to run the entire certification process using simulations. This goal is one of the guiding principles of the German Aerospace Center’s aviation programme. Its approach involves the virtual representation of an aircraft and all of its characteristics throughout its entire lifecycle, from the smallest component to the aircraft as a whole.

Experts across various specialist fields, including aerodynamics, structure, systems and software development, and from a number of the German Aerospace Center’s institutes are working together in the VPH. There are also collaborations with partners in the aviation industry (Airbus, Liebherr Aerospace and others) and with universities (University of Bremen), certification agencies (EASA) and the software industry (SAP). The VPH launch project focuses on the use case of a wing flap and is funded by the state of Bremen and the European Regional Development Fund.

The ideal location for the Bremen Fibre Institute (FIBRE)

Lightweight construction is sturdy, resource-efficient and, of course, lightweight, making it the go-to solution for all types of products. Next-generation fibre composites, a class of materials that combines high-tensile fibres and plastics, play a central role in this. The Bremen Fibre Institute (FIBRE) has been conducting research into these and other materials since 1969. The independent institute, which runs two key sites at the ECOMAT research centre and at Bremen University, can also call on the expertise of the Composite Technology Center (CTC) in Stade and its fibre laboratory at the Bremen Cotton Exchange. Almost 60 of its employees are working on new and improved aircraft components, such as a reconfigured landing flap, window frames and lighter components for inside the plane, as part of a collaboration with Airbus and partners in the field of aeronautical engineering, including the German Aerospace Center, TESTIA and the Leibniz Institute for Materials Engineering. They also work on materials with custom characteristics for applications in the space industry. Today, around half of the institute’s employees work at ECOMAT.

“A particularly interesting and creative aspect of their work is the transfer of materials and related technologies into the products of other industries and markets. These include crash-absorbing elements for small aircraft, orthotics and components for sports cars and agricultural machinery.”

Christoph Hoffmeister, process engineer at FIBRE

Great efforts have been made to deliver ECOMAT’s goal of attracting other players to the new research and development centre in addition to the anchor tenants. Such organisations include SMEs, related service providers and renowned research institutes with links to the key technologies based here. The aim is to make it easier for all involved to share ideas and expertise, and to facilitate fast-track collaboration. ECOMAT tenants include companies, organisations and institutes such as Altran Deutschland S.A.S. & Co. KG (space and aeronautics), Aviaspace Bremen e.V. (space and aeronautics), BK Werkstofftechnik – Prüfstelle für Werkstoffe GmbH (materials testing), the German Research Center for Artificial Intelligence, F&E Technologiebroker Bremen GmbH, InnoWi GmbH (related services), P3 Voith Aerospace GmbH, Premium AEROTEC GmbH, PRIME aerostructures GmbH (space and aeronautics) and the University of Bremen.

A mainstay of aviation and materials research in northern Germany

ECOMAT brings together technologies that are likely to benefit significantly from collaboration and the sharing of expertise. These include lightweight construction, additive manufacturing and 3D printing, materials research, bionics and sensors. Partners in industry, SMEs and renowned research and science institutes have now taken up the reins, and together they are shaping new structures for promising processes and products that will change the face of many industries.

ECOMAT is a mainstay of aviation and materials research in northern Germany, and will focus on new developments in the key areas of lightweight construction, innovative materials and surface technologies. The research and technology centre is an integral element of the 2030 industry and innovation strategy for the federal state of Bremen and the embodiment of the Future of Bremen 2035 – ideas for tomorrow vision. The concentration of expertise at ECOMAT is attracting attention from around the world. It is a powerful signal from the federal state of Bremen and a clear commitment from policymakers to innovation and creativity.

Success Stories

The history of space travel in Bremen

Small circle, big impact: With the founding of the “Development Ring North” (ERNO) in July 1961, Bremen began its development into one of the world’s leading spaceflight locations. Even the return of humans to the Moon would hardly be possible without technology from the Hanseatic city.

Learn moreHow a space enthusiast campaigns for women in STEM fiels and Bremen as a space location

How does someone from a small village in Poland end up working on human spaceflight in Bremen? Dr. Anna Chrobry shares her journey through science, passion, and perseverance—and explains why she proudly calls herself a "space girl."

Learn moreVisions for the future of aerospace

From car navigation systems to weather reports - hardly anything works without satellites. They need fuel, but this is often toxic. The Institute of Aerospace Technology at Bremen University of Applied Sciences is researching environmentally friendly alternatives. What the future of space travel could look like.

Learn more