Artificial intelligence within the maritime industry

Maritime economy and logistics

Artificial intelligence (AI) is now starting to make its way into the maritime industry, with the potential for autonomous systems to be introduced, processes to be made more efficient and safety to be boosted. Keep reading for all the latest on AI applications for shipping and port operations, including a look at some examples alongside the opportunities and potential risks.

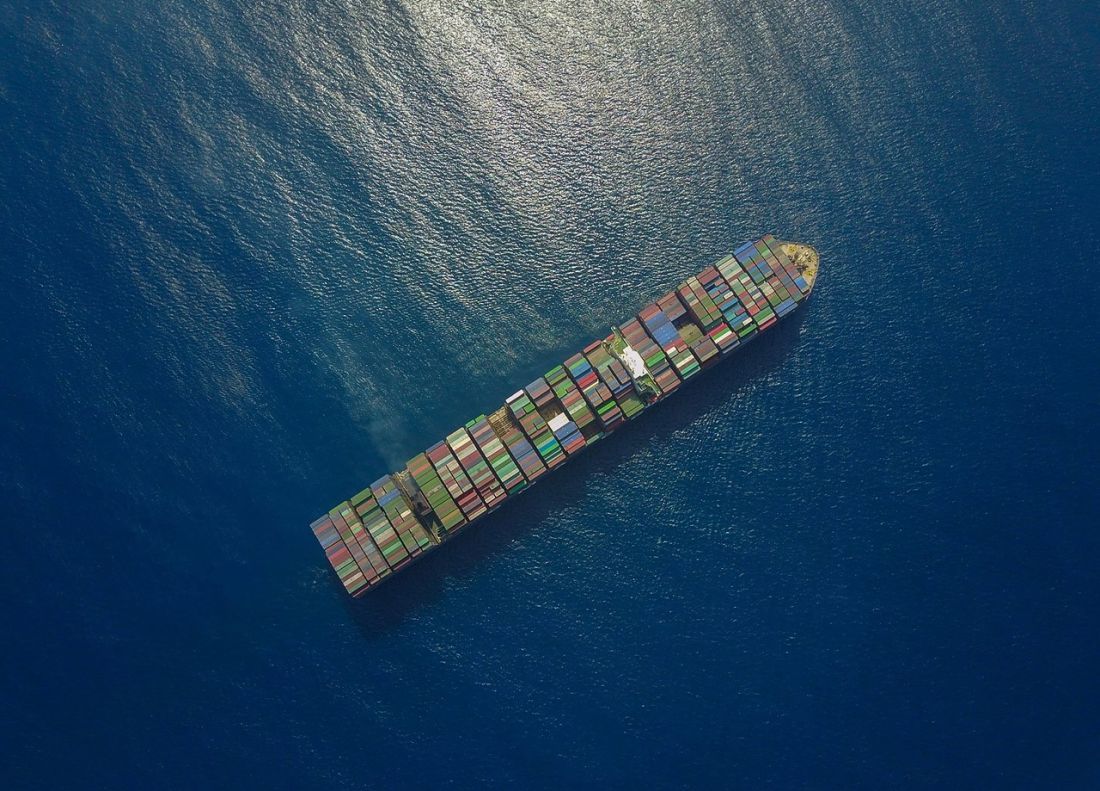

Did you know that 90% of all goods are transported by sea? And the maritime industry is deemed to be one of the most complex sectors around on a global level. After all, it is almost impossible to keep track of all the different key players involved along the transport chain. Then the weather, technology and fluctuations in the market get thrown into the mix, creating an underlying level of uncertainty. As one of the oldest sectors in the world, the maritime industry has traditionally relied heavily on people and their experience. But there is change afoot.

The possibilities afforded by advancing technology do not stop at the ship’s bridge. These days, ocean cruisers double up as floating offices, with data being exchanged in real time between land and sea to enable close contact to be maintained with shipping companies, logistics providers and authorities. System status updates are delivered by sensors and a full ship overview is never more than a click away.

All of this is what we call automation. Now artificial intelligence is set to take things to a whole new level. It opens up the possibility of autonomy in terms of self-control and self-optimisation. This technology is not ultimately restricted to autonomous ships. Individual processes can be, and indeed are, controlled by AI applications too. Captains, shipping companies, crane operators and ship mechanics will have this technology at their disposal in the future and processes and workflows will become more efficient, safe, cost-efficient and manageable as a result.

Contents

1. A brief overview of artificial intelligence

Artificial intelligence is the simulation of human intelligence in machines (German). AI technology can do so much more than process a specific set of commands – it can learn independently, identify patterns, deduce what actions need to be taken, and even implement self-optimisation. In other words, it can process data more quickly, accurately and extensively than humans can. And that makes it a handy solution for all kinds of applications.

AI may have only started hitting the headlines in recent years, but it has been around since the 1950s. It’s just that computing power is only now sufficient to allow for commercial applications. Machine learning (ML), a subset of AI, is of particular interest to industry at the moment. It can be relied upon to derive patterns and rules from existing data and go on to come up with solutions.

If AI technology is to make use of ML, it requires an extensive training dataset. AI systems are trained with a specific purpose in mind, such as controlling a ship, and can then only be used within that context.

The maritime industry is ideal for machine learning algorithms given that huge volumes of data are generated every day in the form of shipping documents, emission information, operating metrics and other documentation. AI systems can be created to deal with all of these aspects effectively.

It is also important to factor in the high costs associated with many shipping processes, where even the slightest of optimisations give rise to considerable savings. AI is sure to be attractive to such a highly competitive industry with notoriously tight margins.

2. AI on ships

AI is set to seriously shake up the commercial shipping sector in decades to come, with the ‘smart ship’ (a fully digitalised, autonomous ship without a crew) as one of the major goals to be achieved. Safety is another important objective given that between 75 and 95% of all accidents at sea are the result of human error and could therefore be largely avoided with the use of AI.

Below are a few examples of areas and technologies currently being worked on.

Examples of autonomous shipping

- Back in 2018, Rolls-Royce and Finnish ferry operator Finferries introduced a fully autonomous ferry called the Falco. Measuring some 50 metres in length, the ferry is designed to cover short stretches and was monitored by an operator from around 50 kilometres away during the initial demonstration of its autonomy.

- Rolls-Royce are currently working on the next step with the Advanced Autonomous Waterborne Applications Initiative (AAWA), a research initiative aiming to develop an autonomous ocean-going vessel. The estimated completion date is set at 2035 for now.

- Another high-profile project is the Yara Birkeland, a container ship measuring 80 metres in length that is designed to transport fertiliser on autonomous journeys powered fully by electricity.

- The EU is currently funding the AUTOSHIP project to develop two autonomous ships – one for short sea shipping and the other for inland waterways – with the initial results expected by 2023.

- As part of a research project on a smaller scale, the Mayflower Autonomous Ship is a trimaran set to become the first ship to cross the Atlantic on a fully autonomous voyage in 2021.

All of these examples demonstrate that the concept of a fully autonomous commercial ship is currently still at the early stages of development. A good few decades will still have to pass before we can expect to see large numbers of autonomous ships sailing the seven seas. Arne Berger, a researcher at the Bremen Centre for Industrial Mathematics (ZeTeM)(German) and an expert in maritime AI, agrees with this assessment: “It takes quite some time for new systems to really catch on since ships have long service lives. I would estimate that autonomous ships won’t be used on a commercial basis for another 20 to 25 years,” he says. “The implementation of AI is starting off with baby steps.”

Partially autonomous systems within the maritime industry

With those estimates in mind, many companies and projects are focusing on partial autonomy, assistance systems and niche solutions. For example, the ZeTeM in Bremen is working on a project called Galileo Nautic 1+2 (German), which aims to create an automated system to prevent collisions between ships in offshore locations. “We urgently need assistance systems to allow us to get a grip on the growing level of complexity. Captains are very open to this kind of technology,” explains Berger. AI systems are also being developed in many other areas of shipping:

Navigation

Route optimisation is viewed as one of the ‘low-hanging fruits’ as far as AI is concerned given that large volumes of predominantly high-quality data are available and already digitalised, meaning that there is not much need for new technology.

- The partnership between Hong Kong-based Orient Overseas Container Line (OOCL) and Microsoft is one high-profile example. Within the parameters of this project, the shipping company is using the large volume of data generated by its fleet to be able to better predict when vessels will arrive at the quay, for instance, with a view to coordinating port activity more effectively. The company is aiming to save over ten million dollars.

- Another project, Map Borealis by start-up Drift&Noise, is using satellite data to optimise the route across the Arctic Ocean and save considerable amounts of time and money in the process.

- The Orca AI project aims to provide assistance systems for ports and offshore vessels. The project combines sensor data from thermal and ultra-low-light cameras to add image recognition to positioning systems and maritime radars. This image recognition is powered by an ML algorithm, allowing for collisions to be avoided along with information overload in the ship’s bridge when navigating busy waterways. SenseTime in Hong Kong is pursuing a similar approach.

Safety

The previous section outlined how smart navigation systems will be able to detect and prevent collisions in the future, which will help improve safety on board ships.

And the systems themselves can benefit from AI too. Cybersecurity (covered in greater depth below) is one of the major digital challenges being faced in modern society. Cyber attacks can put individual ships and processes out of action but they can also affect entire ports and soon bring the entire logistics chain to a standstill (German). AI-based security systems can monitor the digital flow of data and respond quickly if they pick up on any anomalies.

- The two podcast episodes by the North Germany Maritime Cluster (only in German) delve deeper into the issue of cybersecurity within the maritime industry.

Energy consumption

Many of the ongoing AI projects aim to optimise routes and processes, with the welcome knock-on effect of reducing fuel consumption. But energy efficiency is another important aspect of AI projects in its own right.

- For example, Stena Line has been using AI to experiment with the reduction of energy consumed by ferries travelling between Gothenburg and Kiel since 2018. The Norwegian company uses data on the weather and current together with other variables to identify the most efficient route at any given moment. Test results have revealed potential fuel savings of 3%.

- German start-up Marine Digital also provides a fuel optimisation system, which uses environmental and ship data to optimise routes as part of an automated process.

3. AI in ports

After shipping, ports are the next logical port of call for AI technology. There is plenty of potential for optimisation given the incredible number of key players involved combined with the large volumes of data associated with compulsory documentation, sensors, machinery and other equipment. It is often the case that individual parties are not sufficiently interconnected and data is rarely exchanged using uniform digital standards. Much of the work going on in a port is therefore likely to be quite segregated with no requirement for data to be exchanged between the various companies involved. But change is on its way...

- Take the example of Timetoport, developed by the Port of Rotterdam. The system uses the freely available data from the ship automatic identification system (AIS) to calculate a ship’s expected time of arrival at the port. This allows for the deployment of tugs and mooring services to be better planned, for example.

- The Port of Antwerp is also trying out a system using AIS data and additional cameras to track where ships are positioned in the port and in turn optimise the flow of traffic and avoid congestion.

- Several projects using AI algorithms to automate processes are or have been based in Bremerhaven too. Port operator EUROGATE tested out automated straddle carriers as a way of transporting containers to ships as part of the STRADegy project. The idea behind the OBELiSK (German) project is to control the floodlights within the extensive port area so that they are only switched on when and where they really need to be. The RANG-E (German) project focused on autonomous shunting on the port’s railway tracks with a view to optimising the port’s infrastructure. And the ISABELLA project aims to improve car manoeuvres by conducting research in the car terminal run by logistics company BLG.

In a port setting, AI is tied in closely to robotics, as many AI systems have robotic elements that allow for tasks to be performed autonomously. Robots are set to work alongside vehicles to unpack shipping containers and complete other tasks.

In a similar vein to the smart ship concept, the ultimate goal of these developments is a fully digitalised smart port, where data is exchanged across the entire logistics chain and AI is used to optimise processes. A central concept here is the ‘digital twin’, which involves a complete digital map of all processes taking place within the port setting.

4. AI in underwater applications

Underwater work is often dangerous and strenuous. But there’s a lot of it to be taken care of. Offshore wind farms, oil rigs, port facilities, submarine cables and the hulls of ships need regular inspections and maintenance work. The opportunity to automate these processes, and in turn reduce the associated risks for workers and improve the available data, is one of the main motivating factors behind the development of robotic AI applications in particular. There is no end of challenges to overcome here, relating to everything from communication and object detection to interaction with items underwater.

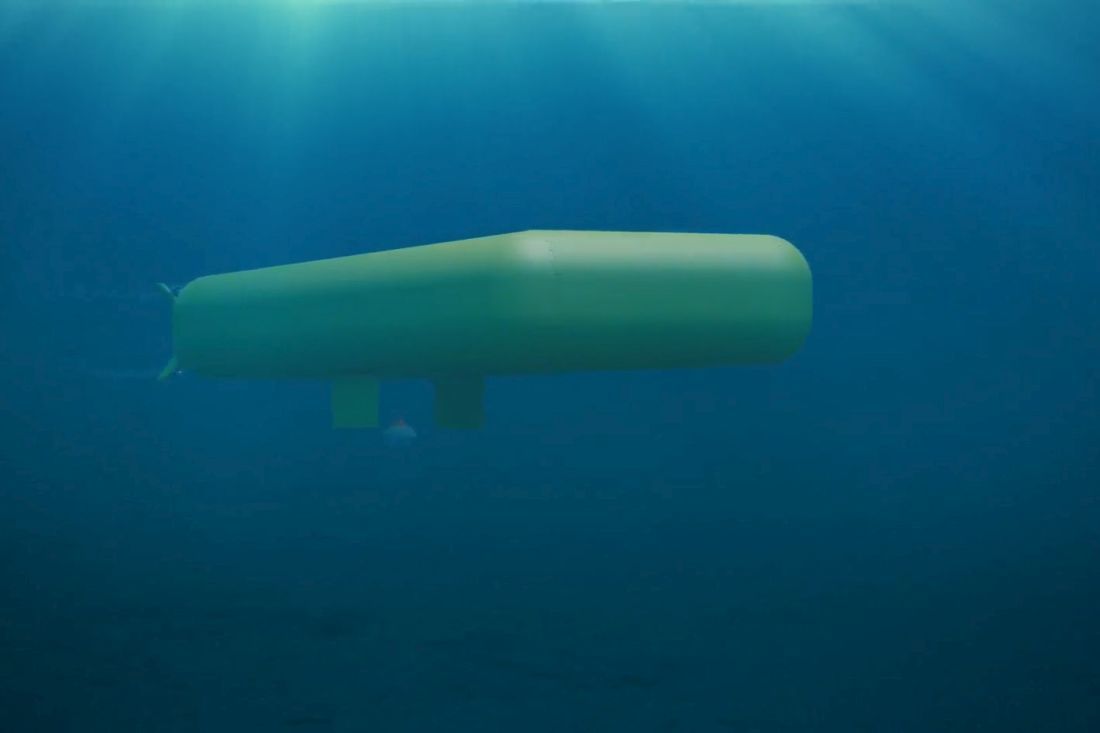

- Work is currently underway on the largest autonomous research submarine yet. As part of the MUM project, a modular submarine measuring up to 50 metres in length is being created and will ultimately be able to travel autonomously underwater.

- The HullSkater is a type of robotic vacuum cleaner designed specifically to autonomously inspect and clean the hulls of ships.

5. AI used by maritime service providers and shipbuilders

The huge potential offered by AI is all the more apparent as you work your way along the entire logistics chain and consider maritime services too. One key area here is:

Maintenance and inspection

Collecting machinery data and status updates is part of the daily routine within the maritime industry. In some cases, the traditional logbook still has its place. But monitoring machinery and systems digitally is commonplace within the ship’s bridge and engine room these days. And this basic level of monitoring will evolve into predictive maintenance in the future. AI technology can use past data to determine maintenance intervals and, most importantly, predict the condition of individual parts or entire systems and assess what level of maintenance they will require.

- One example of this is Wärtsilä’s Expert Insight – a system that monitors the Finnish manufacturer’s ship engines and is designed to provide proactive assistance to maintenance crews.

Going forward, AI will not only be relied upon to monitor sensor data. It will also be used in drones as a way of overseeing ships and port facilities. The fact that drones can move around makes them an ideal solution for keeping tabs on the many inaccessible areas such as ship superstructures, cranes and fuel depots.

- The ADRASSO drone is one example that is used to inspect ballast tanks and the like.

Insurance

Artificial intelligence will bring about major changes within the insurance sector. After all, the technology will make it possible to trawl through much larger volumes of data and come to more specific conclusions than would otherwise be possible. Not to mention that real-time data taken directly from ships will be incorporated into modelling.

- London-based start-up Concirrus uses AI to analyse data held by marine insurance firms and optimise policies on that basis. On top of that, ships are monitored in real time to keep track of protection on journeys through insured and uninsured waters, for example. The start-up suggests that costs are improved by 10 to 25%.

- Insurwave is a start-up that uses AI and blockchain to automate a number of tasks to make them secure and transparent.

AI drastically cuts down on the amount of work required, speeds up processes and allows for much more data to be leveraged when calculating premiums than would be possible without the technology. As a result, ships and the like can be assessed in much greater detail. Insurance companies can use the time they have saved to improve their customer service or allocate it to special cases where AI does not prove to be quite as useful.

Shipbuilding and shipyards

When it comes to shipbuilding, AI is initially set to be predominantly used for designs and process optimisation. As we have seen in other industries, engineers will use artificial intelligence to help them design ships in the future. Computers can help make this process more efficient by automatically integrating all kinds of requirements and parameters. Generative design also makes it easier to design structures while saving on costs. The digital twin concept is going to be key in shipbuilding too, as it will allow for a full digital replica of a ship to be created and application profiles to be simulated.

- Robots are also set to take on a bigger role within the field of shipbuilding. Daewoo Shipbuilding & Marine Engineering provides a good example of this with its tests on a robot to be used to process metal plates.

6. Opportunities and risks associated with AI technology

All of these examples show that a great deal of effort is going into AI solutions in more or less every branch of the maritime industry. The optimisations promised by these applications are set to lead to considerable savings, giving the companies involved a serious competitive edge in the not-too-distant future.

So will companies be left behind if they do not go down the AI route? Many of the projects are still at the early stages of development, with plenty of R&D to be invested in them yet. And yet the transition from research project to real-life application can be surprisingly speedy.

Risks of AI developments within the maritime industry

Validation and trust

Testing autonomous systems at sea is much more complex than the equivalent process within the automotive industry. Cars are limited in size and their range of action is easy to predict, which means that setting up the relevant tests is straightforward. There is a lot more work involved in testing AI applications on a ship. For one thing, it is harder to access systems out at sea. Plus, the costs are higher and there is more chance of a serious incident occurring. Unexpected situations often arise at sea and in port settings. So how can an AI solution be expected to prove that it can be trusted to make the right decisions beforehand?

“It will be really interesting to coordinate the interaction between AI and man, as we find that the decisions made by artificial intelligence are sometimes pretty hard to follow. That’s one of the major challenges faced in many sectors – not just in the case of underwater vehicles,” explains Dr Jeronimo Dzaack, Head of Technology, Innovation and Sustainability at ATLAS ELEKTRONIK, who is working on the MUM submarine project (as outlined above).

Data integration

AI needs data. And the principle “the more the better” often applies. In other words, companies looking to develop AI technology need to have enough data at their disposal or at the very least need to start collecting data. In the case of projects that span multiple supply chains and involve several service providers, all parties have to be willing to provide data and interfaces. Although these kinds of collaborative projects often equate to the greatest potential for optimisation for everyone involved, it can be tricky to convince third parties to contribute their data.

Time, manpower and investment

AI projects require time – at least somewhere between six and twelve months – and plenty of resources. Given that medium-sized companies are unlikely to have the relevant development capability in house, they need to bring in people in the know. AI specialists are hard to find and cost a pretty penny when you do find them.

One way around this is to work with research and funding institutions, such as the Mittelstand 4.0 centres of excellence for medium-sized companies (German) or the Maritime Cluster Northern Germany. The NautilusLog project (German) is a great example of a successful partnership, with a digital logbook having been created using a ship simulator that the start-up with the same name as the project was able to use while keeping costs neutral.

Compliance and regulations

Maritime regulations sometimes lag slightly behind advancements in technology. This is even more evident when it comes to AI and robotics applications.

Cybersecurity

With more reliance on networking and digitalisation comes a greater risk of cyber attacks. And so it is vital that cybersecurity is always given due care and attention as part of AI projects.

People’s attitudes to work

When we hear mention of ‘artificial intelligence’, images of workforces being replaced by machines come to mind – even more so if robots and autonomous vehicles are involved. This underlying fear can cause employees to feel anxious and concerned. In the worst case scenario, they may sabotage AI projects or be reluctant to even start working with this technology.

The ability to address these worries through open communication and training is key if AI projects are to prove successful. This technology is still in its early stages and has a long road of development ahead of it within the maritime industry. Right now, assistance systems are the order of the day. They are designed to make people’s jobs easier and allow us to gain better control over our networked world as its complexity continues to increase.

Plus, we mustn’t forget that we are faced with an ever-dwindling workforce thanks to our ageing population. If we don’t call on robots to help us, there will come a day when we are unable to do everything we need to do to keep our globalised economy running.

Opportunities presented by AI developments within the maritime industry

As outlined above, AI provides a way to optimise processes in virtually every branch of the industry, allowing for time and money to be saved. For this to be possible, data has to be available or there needs to at least be a way of collecting data.

We recommend that companies looking to get involved with AI follow these top tips:

- Start small: Don’t try to dive in at the deep end with full automation. Instead, it is much better to start small in an area where data is already available.

- Get help: There is plenty of help on hand for medium-sized companies, with services being offered by the likes of the Mittelstand 4.0 centres of excellence. In fact, Bremen has been identified as an ideal location for AI applications. The state is ready to help medium-sized companies with numerous initiatives and funding opportunities, underpinned by the AI strategy and AI centre of excellence currently under construction in Bremen(German).

- Be open-minded: It can be a brilliant idea to network and collaborate with competitors or suppliers in certain areas because it means that more data will be available to you and AI systems will be more precise.

- Stay informed: Even if you’re not exactly going to be taking the lead on AI programming yourself, you should at least stay up-to-date with the latest developments. And that applies whether you’re an engineer or a management executive. Most importantly, you need to have an understanding of what AI can do and where its limitations lie.

7. Conclusion

Our overview of AI within the maritime industry has revealed that work is underway to introduce AI technology across the board, but we are still a long way away from widespread application at the moment. Although many projects are at the testing stage, initial commercially viable solutions do exist in some areas. Fully automated ships may be decades away, but niche applications can come about all of a sudden.

The introduction of AI technology is in line with the increasing level of networking within the industry. Data is collected and exchanged in real time on an unprecedented scale. AI will provide huge benefits in the face of the relentless speed of global processes and the complexity of the maritime supply chain given that it helps make things more manageable for us humans.

Success Stories

10 Leading Coffee Companies from Bremen

From trading to roasting to logistics – no one does coffee quite like Bremen. But who are the players driving the business in Germany’s coffee capital? Meet ten of them.

Learn moreProfile of Bremen's eight ports

Bremen's ports are the engine that drives economic activity throughout the region. But do you know which goods arrive and depart, and where? We have taken a look around the eight port complexes in Bremen.

Learn moreThe Polymath from Horn-Lehe

No can do? No such thing! GERADTS GMBH makes the things other companies can’t even imagine. This is why this engineering firm is so firmly rooted in major European aviation and aerospace projects, and also in a myriad of other sectors.

Learn more