From the Weser into Outer Space

AerospaceTechnology from Bremen is driving forward the return to the Moon

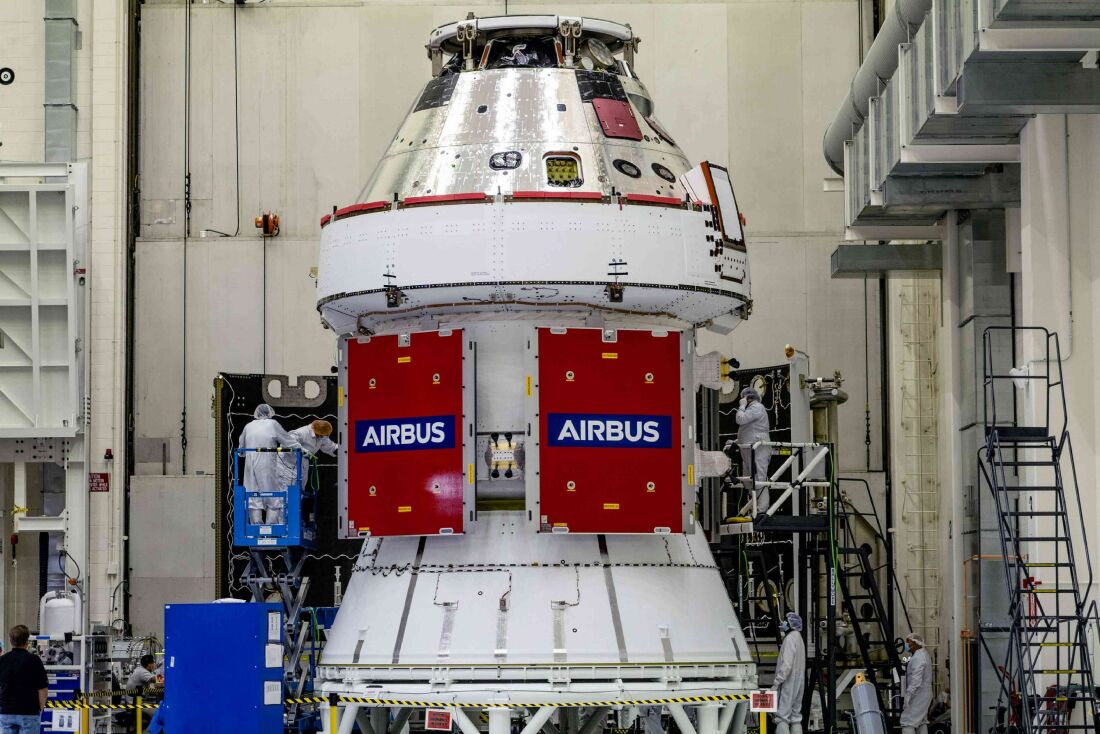

It looks like a huge cylinder: four metres high and four metres in diameter. The module is called ESM 3 and it is a central component of the USA's Space Agency NASA's new Artemis Moon-landing mission. ESM stands for "European Service Module". In three years time, its powerful rear-mounted rocket engine will drive NASA's "Orion" spacecraft and take four astronauts to land on the Moon for the first time since 1972. That this mission will enable a woman to set foot on the Moon is not the only "first" for this journey into a new era of space travel. The ESM 3 is the first system-critical component of a major NASA project that the Agency has allowed to be developed and built outside the United States... and it's being built in Bremen.

"The Americans have realised that it makes neither technological nor financial sense to implement such large-scale projects single-handedly", said René Kleeßen, Space Programme Director at the German Aerospace Center (DLR). After creating a prototype and the module for the first test flight, Airbus Defence and Space in Bremen started work on the crucial "number three" module.

Delivery vehicle to supply future stations on the Moon

For many years, engineers and scientists from Bremen have been indispensable members of the teams of experts involved in the global space exploration scene. The Columbus laboratory, which is Europe's contribution to the International Space Station (ISS), the ATV space shuttle used to supply the ISS, satellites and the top stage of the European launch vehicle Ariane: these projects, all created in Bremen, have helped the Hanseatic city become one of the world's most important centres of space exploration. Now, Bremen is reaching for the Moon!

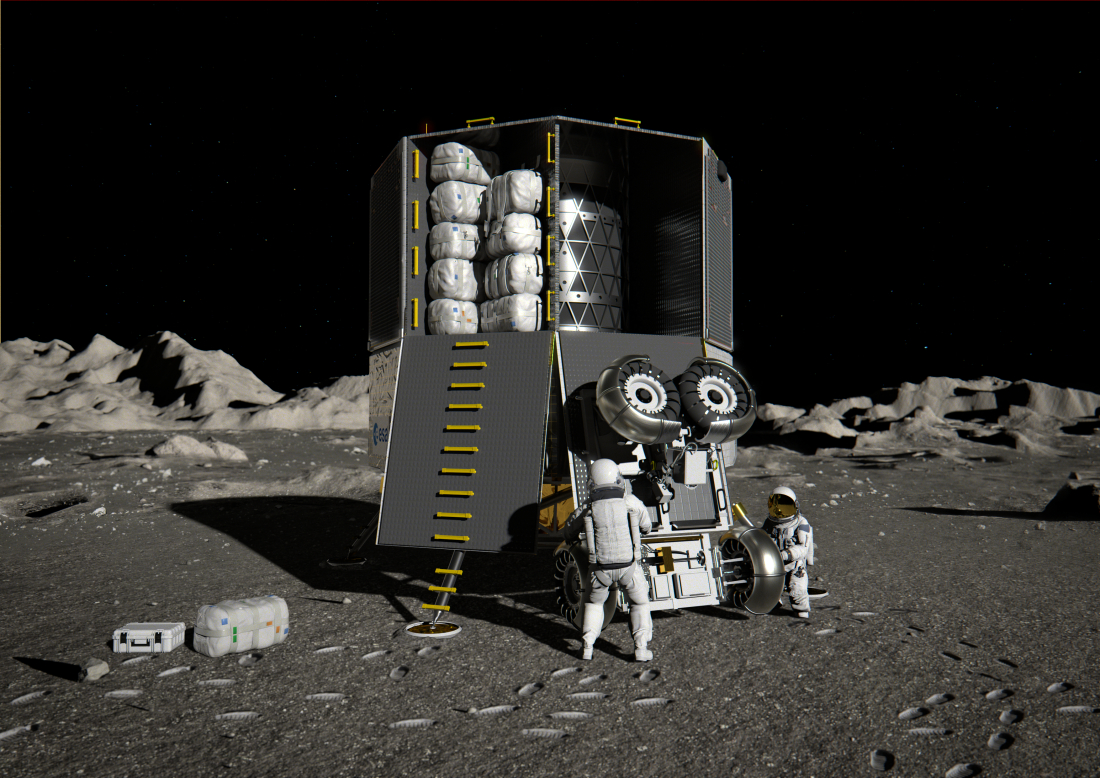

Once building the ESM had almost become routine, the next major project came along. Before the end of this decade, the "European Large Logistic Lander" (EL3) will be the first large European space vehicle to land on the Moon. It will be a lunar delivery vehicle and unload material for a future station on the Moon's surface. An initial concept is currently being created at Airbus in Bremen: "We need to find new design methods that enable us to take along as much payload and fuel as possible", said Thomas Diedrich, who has responsibility for future "Space Exploration" projects at Airbus Defence and Space.

European commitment to space research

The material transporter for long-term missions on the Earth's satellite is more than a complex technical creation. It is also Europe's commitment to space research. "In the same way that Ariane 6 guarantees us independent access to space, the "Large Logistic Lander" will guarantee European access to the Moon", stated Kleeßen. However, the European Moon mission will be exclusively robotic. "We don't have the financial resources to take humans to the Moon", said Bernado Patti, ISS and Exploration Programme Manager at the European Space Agency (ESA). For a crewed mission, "our budget would have to be five times greater", he said.

The European launch vehicle, Ariane 6, whose top stage is being developed and built in Bremen, plays a decisive role in Europe's future mission to the Moon: "We want to use Ariane 6 to take the Lander to the Moon", said Patti. That means that the EL3 can have a diameter of 4.5 metres and be a maximum of six metres high. Its weight is limited to 8.5 tonnes. This is as much as Ariane 6, augmented by four boosters, can carry to the Moon.

Car bumper as a model for moon-landing technology

The weight limit, the required payload of up to 1.7 tonnes, and the amount of fuel needed to reach the lunar surface, present Bremen's aerospace engineers with especial technological challenges. "Unlike Mars, the Moon does not have an atmosphere that would have a braking effect during a landing", explained Diedrich. For this reason, the Lander's rocket engines must be used as a brake. That requires a great deal of fuel, whose weight must not reduce the volume of the possible payload. "We must find new approaches that will enable us to greatly reduce the Lander's unladen weight", said Diedrich.

Solving this challenge requires detailed concepts. Instead of using heavy struts to absorb the impact of landing on the Moon's surface, like the old American lunar modules did, the researchers in Bremen want to use a principle that was actually developed in the 1970s for robust car bumpers. "We're thinking about similar honeycomb structures that can be deformed and then return to their original shape", said Diedrich.

3D printed rocket engines will reduce costs

The lunar transporter's engine could also have a close connection to Bremen. The ArianeGroup is currently building an entirely new engine, called "Berta", to be used specifically with the third stage of Ariane 6, which is being developed in Bremen. The special thing about "Berta" is that it is possible to print parts of the rocket engine on a 3D printer, making them much less expensive to produce.

However, the actual technological challenge is the Lander's control system: the vehicle will manage its descent from lunar orbit and select a suitable landing site within a predefined area completely autonomously, without any possible external human intervention. The Space Research team at Airbus in Bremen qualified for the Lander project by developing the ATV automatic space transfer vehicle used to supply the ISS. Now, the experts are adding artificial intelligence, because the landing vehicle has to make split-second decisions during its descent from lunar orbit to the surface. "Sadly, stopping several hundred metres above the surface and taking time to think is really not an option", explained Diedrich.

Filling station from Bremen for the service station in space

In contrast, the lunar landing for the astronauts will be comparatively gentle. The crews of the future stations on the Moon will first stop at a "service station" in space. At this "Lunar Gateway", they will board a "transfer bus" that will take them down to the satellite's surface. Engineers from Bremen, working for the space research company OHB Systems, are involved with this outpost for expeditions to the Moon. Working on behalf of Thales Alenia, the Franco-Italian technology group, they are building the "ESPRIT" refuelling module that will supply spacecraft with fuel. Although the Lunar Gateway won't become a reality until the end of this decade, it will then play a special role in international space travel: it is NASA's proposed staging point for crewed missions to Mars.

However, it is the Moon that is of greatest interest to the European Space Agency. For this reason, ESA and NASA often trade equipment and expertise. The ESM module is being built in Bremen in return for Europe's participation in the International Space Station. The EL3 "European Large Logistic Lander" could bring in an even greater prize in return: a place in the American lunar module. "It is possible that we could take a European astronaut to the Moon before the end of this decade", said ESA specialist Bernado Patti.

Success Stories

The history of space travel in Bremen

Small circle, big impact: With the founding of the “Development Ring North” (ERNO) in July 1961, Bremen began its development into one of the world’s leading spaceflight locations. Even the return of humans to the Moon would hardly be possible without technology from the Hanseatic city.

Learn moreHow a space enthusiast campaigns for women in STEM fiels and Bremen as a space location

How does someone from a small village in Poland end up working on human spaceflight in Bremen? Dr. Anna Chrobry shares her journey through science, passion, and perseverance—and explains why she proudly calls herself a "space girl."

Learn moreVisions for the future of aerospace

From car navigation systems to weather reports - hardly anything works without satellites. They need fuel, but this is often toxic. The Institute of Aerospace Technology at Bremen University of Applied Sciences is researching environmentally friendly alternatives. What the future of space travel could look like.

Learn more